A hydraulic fluid level sensor is an instrument that is used to measure the level of hydraulic fluid in a system. It is typically used in hydraulic systems that operate machinery, such as press brakes, shears, presses, and other industrial machinery. The sensor is used to monitor the level of oil in the system, and to alert the operator when the oil level is low.

How Does It Work?

The hydraulic fluid level alarm works by measuring the level of hydraulic fluid in the system. The sensor is typically mounted on the side of the system and uses a combination of pressure, temperature, and light sensors to provide accurate readings of the fluid level. The pressure sensors measure the hydraulic pressure in the system, and the temperature sensor measures the temperature of the fluid. The light sensors measure the amount of light that is reflected off the surface of the oil. This information is then used to calculate the level of fluid in the system.

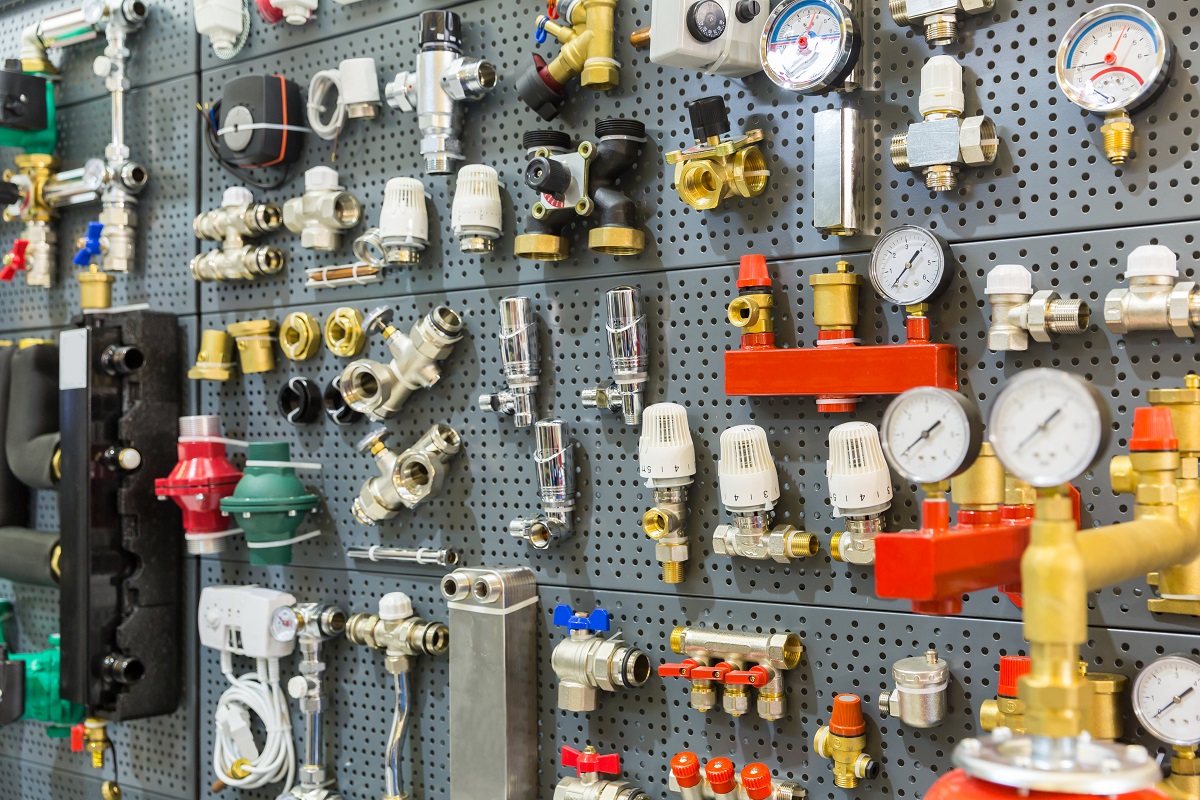

Image Source: Google

Benefits of Using a Hydraulic Fluid Level Sensor

Using a hydraulic fluid level sensor can provide numerous benefits for a hydraulic system. The most important benefit is that it can help to reduce downtime due to low oil levels. This can help to improve the efficiency of the system, and can help to prevent costly repairs. In addition, the sensor can help to reduce the risk of leaks in the system. Leaking hydraulic fluid can cause serious damage to the system and can be a safety hazard. By monitoring the fluid levels, the risk of a leak can be reduced.