When it comes to precision cutting, electroplated diamond wheels are a game-changer. These cutting tools are known for their exceptional performance and longevity, making them a popular choice in various industries such as glass, ceramics, stone, and composites. In this ultimate guide, we will explore everything you need to know about wheels of electroplated diamond wheels and how you can unleash their power for precision cutting.

What are Electroplated Diamond Wheels?

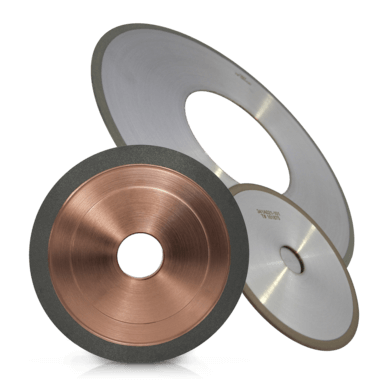

Electroplated diamond wheels are precision grinding wheels with diamond grains electroplated onto the surface using a nickel plating process. This unique manufacturing method ensures that the diamond grains are firmly held in place, providing excellent cutting performance and longer lifespan compared to other types of diamond wheels.

Key Features of Electroplated Diamond Wheels:

- High precision cutting performance

- Longer lifespan

- Ability to maintain sharpness over time

- Suitable for both wet and dry cutting applications

- Available in various shapes and sizes for different cutting purposes

Applications of Electroplated Diamond Wheels

Electroplated diamond wheels are widely used in a variety of industries for precision cutting applications. Some common applications include:

1. Glass Cutting

- Perfect for cutting glass materials with precision and smooth edges

- Used in the production of mirrors, windows, and glass artworks

2. Ceramic Cutting

- Ideal for cutting ceramic tiles, pottery, and other ceramic materials

- Ensures clean and precise cuts without chipping or cracking

3. Stone Cutting

- Used for cutting granite, marble, and other natural stones

- Provides accurate cuts for stone fabrication and construction projects

4. Composite Cutting

- Effective for cutting composite materials such as fiberglass, carbon fiber, and composite panels

- Ensures high precision cuts for composite manufacturing and aerospace applications

Tips for Unleashing the Power of Electroplated Diamond Wheels

To maximize the performance of electroplated diamond wheels for precision cutting, consider the following tips:

1. Choose the Right Wheel

- Select the appropriate wheel size and shape based on your cutting requirements

- Consider the material being cut and the desired finish

2. Optimize Cutting Parameters

- Adjust cutting speed, feed rate, and depth of cut for optimal performance

- Ensure proper coolant or lubrication for effective heat dissipation

3. Handle with Care

- Avoid excessive pressure or side loading during cutting operations

- Store and handle the wheels properly to prevent damage or contamination

4. Regular Maintenance

- Inspect the wheel regularly for wear and damage

- Clean the wheel surface to remove debris and maintain sharpness

Conclusion

Electroplated diamond wheels are essential tools for precision cutting in various industries. By understanding their features, applications, and maintenance tips, you can unleash the power of these cutting tools for exceptional performance and quality cuts. Remember to choose the right wheel, optimize cutting parameters, handle with care, and perform regular maintenance to ensure long-lasting performance and efficiency.