If it comes to almost any company, the upkeep of all of the equipment and machines is extremely important.

This is particularly true with gas and oil businesses. Proper and regular maintenance of pipelines is quite significant not just for the improvement of the organization but also for the security of the employees. You can also manage your assets for maintaining power through the energy transition by hiring professional engineers.

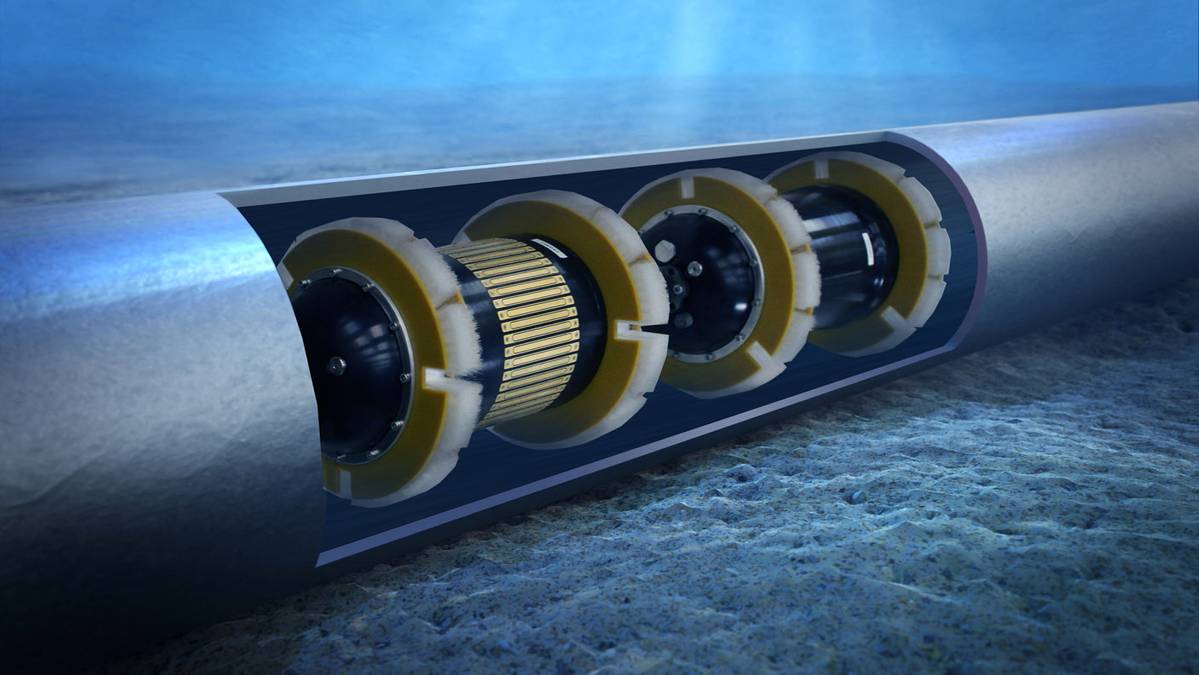

Image Source: Google

A scheduled pipeline review is actually crucial for gasoline and petroleum businesses. This package of providers makes sure potential problems are discovered early on and the proper steps are enforced to mend those.

How can both of these smart pigging systems compare to another? Following is a brief look at the benefits and disadvantages of each one of those systems. Concerning dimensions, UT may take dimensions 1,600 times per minute.

MFL, on the flip side, magnetizes lines so as to quantify flux leakage. With MFL, outcomes are available two to three weeks following the first tests. This is because specialists will need to analyze the information.

By comparison, results for UT are instantly available as a result of straightforward and easy to comprehend analysis. MFL demands the usage of tools that are large, frequently weighing hundreds of kilograms.

Subsequently, those tools require that the use of cranes for launching an important clearing. UT, on the other hand, uses lighter and smaller tools and maybe launched without needing the use of lifting gear.

UT tools may also be found even in suburban spaces. MFL may be utilized for many different media such as liquid and gas while UT can simply be used for fluids. But, UT may be utilized in gasoline lines in batching.